From the diamond in the wedding ring to the steel and cement used in the construction of houses, and the coal used in the generation of electricity, are all extracted from deep inside the earth. The mining industry is the reason for all the luxuries we have around us.

The mining industry is rapidly undergoing transformation these days. Bringing innovation in mining companies has become crucial mainly for the safety of miners. Internet of Things (IoT) is an emerging technology that is bringing a positive change to the mining industry.

Understanding the Internet of Things

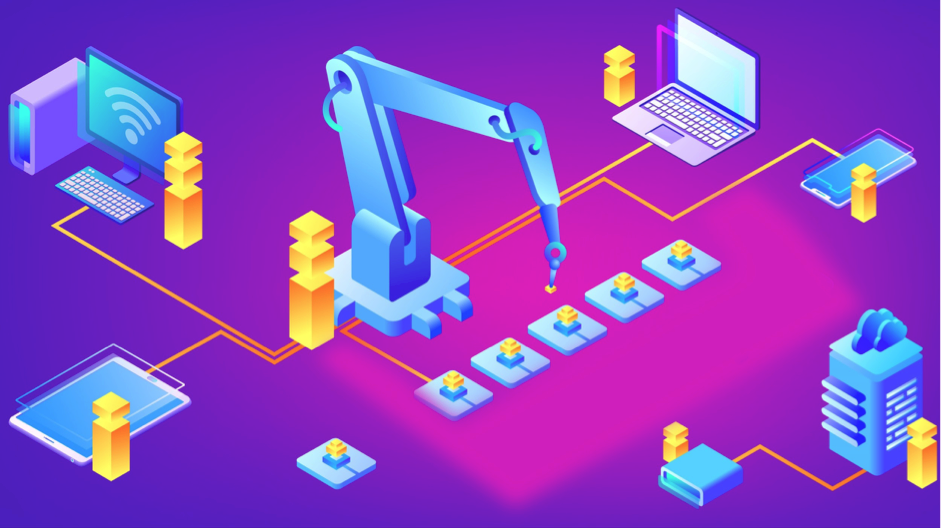

Internet of Things is the interconnection of computing machines, sensors, controllers, integrated circuits, and embedded devices communicate with server through internet. This future generation network technology is being utilized in transforming the mining industry by providing various ways to maintain the safety of miners and enhancing productivity. The technology involves seamlessly connecting equipment, devices, and people to each other.

How the Mining Industry is Utilizing IOT

Enhanced discovery

Remote IoT devices can be used to discover resources deep inside the earth without any human intervention.

Agile workflow

Real-time monitoring of operational processes using sensors provides instant visibility. This allows for developing new business models that can take advantage of highly agile processes. The remote, real-time monitoring of these operations provides enhanced efficiency, decreased variability and efficient identification. For example, mining output can be observed in real-time and transport can be scheduled automatically.

Safer working conditions for miners

Miners risk their lives for bringing all these things for the world which is the most hazardous jobs of all. Think of a human being working miles beneath the surface of the earth in most hazardous circumstances and due to anything an accident occurs at the site, it is a dreadful situation that becomes a threat to life. When the miners will be already acquainted with the location of the equipment and the environment conditions around them, then safer circumstances will be created for working. The real-time data that will be accumulated using the devices and networks will be helpful in predicting the working conditions of mines.

Remote operations of machines

Mining equipment can be operated remotely with the help of sensors and actuators. This removes the need for miners to risk their lives by working in hazardous conditions.

Predictive and preventive maintenance

Using sensors the status of mining equipment and components within them can be continuously monitored. This sensor data provides a basis for analytics that is utilized for predicting failures before actual occurrence. This allows timely intervention to order and replace the failing component in time and avoid costly interruptions and delays.

Mining vehicles have built-in sensors to measure temperature, contamination, tire pressure, frame rack, bearing rotation, bias and pitch, vibration, frame rack, brake pressure and speed of engine. The data is transmitted remotely and used to make maintenance schedules so that the alert teams can work before any problem occurs.

Analytics and insights

Visualization tools can provide 3D displays of the mine and other data. They can be used by pit controllers, geologists, drilling/blasting teams, supervisors and mining planers. This automation of mining process has given the ability to instantly gather and analyze environmental and equipment data in order to carry out risk and area assessments.

Use of IoT is tremendously benefiting mining operations. Use of IoT in various areas has reduced human operatives needed in dangerous environments, allowed real-time monitoring with safety alerts, and efficient operations. IoT is changing the mining sector from a dangerous and hazardous place to a fully automated and a safe place for people to work.